The Guidebook to Toyota's 13 Pillars System - Series Books 7 to 17. Toyota Production System Concepts

Par :Formats :

Disponible dans votre compte client Decitre ou Furet du Nord dès validation de votre commande. Le format ePub protégé est :

- Compatible avec une lecture sur My Vivlio (smartphone, tablette, ordinateur)

- Compatible avec une lecture sur liseuses Vivlio

- Pour les liseuses autres que Vivlio, vous devez utiliser le logiciel Adobe Digital Edition. Non compatible avec la lecture sur les liseuses Kindle, Remarkable et Sony

- Non compatible avec un achat hors France métropolitaine

, qui est-ce ?

, qui est-ce ?Notre partenaire de plateforme de lecture numérique où vous retrouverez l'ensemble de vos ebooks gratuitement

Pour en savoir plus sur nos ebooks, consultez notre aide en ligne ici

- FormatePub

- ISBN8227484536

- EAN9798227484536

- Date de parution04/12/2023

- Protection num.Adobe DRM

- Infos supplémentairesepub

- ÉditeurBig Dog Books, LLC

Résumé

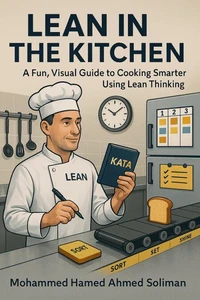

Master the full depth of the Toyota Production System (TPS) with this essential guidebook series-Books 7 to 17, bundled in one powerful collection. Designed for lean practitioners, managers, engineers, and students of operations excellence, this box set explores the foundational principles that transformed Toyota into the most efficient automaker in the world. Rooted in just-in-time (JIT) and jidoka (built-in quality), TPS is much more than a manufacturing tool-it's a philosophy of continuous improvement, flow, and respect for people.

This book set breaks down Toyota's 13 core pillars and shows how they work together to eliminate waste, ensure quality, and increase productivity. You'll discover: The historical roots of TPS-from Sakichi Toyoda's self-stopping loom to Taiichi Ohno's system-wide innovations after WWII How Kiichiro Toyoda developed the Just-in-Time concept to eliminate overproduction How Toyota built a system of continuous improvement (kaizen) using the PDCA scientific method Why jidoka empowers machines and people to prevent defects in real-time How TPS principles apply not just in Japan-but across global industries This box set includes Books 7 through 17 in the TPS Series-perfect for professionals who want to accelerate learning and drive lean transformation in their own organizations.

If you're serious about understanding the thinking behind Toyota's success and want a practical, in-depth, and historical overview, this set will guide you through the full system step by step.

This book set breaks down Toyota's 13 core pillars and shows how they work together to eliminate waste, ensure quality, and increase productivity. You'll discover: The historical roots of TPS-from Sakichi Toyoda's self-stopping loom to Taiichi Ohno's system-wide innovations after WWII How Kiichiro Toyoda developed the Just-in-Time concept to eliminate overproduction How Toyota built a system of continuous improvement (kaizen) using the PDCA scientific method Why jidoka empowers machines and people to prevent defects in real-time How TPS principles apply not just in Japan-but across global industries This box set includes Books 7 through 17 in the TPS Series-perfect for professionals who want to accelerate learning and drive lean transformation in their own organizations.

If you're serious about understanding the thinking behind Toyota's success and want a practical, in-depth, and historical overview, this set will guide you through the full system step by step.

Master the full depth of the Toyota Production System (TPS) with this essential guidebook series-Books 7 to 17, bundled in one powerful collection. Designed for lean practitioners, managers, engineers, and students of operations excellence, this box set explores the foundational principles that transformed Toyota into the most efficient automaker in the world. Rooted in just-in-time (JIT) and jidoka (built-in quality), TPS is much more than a manufacturing tool-it's a philosophy of continuous improvement, flow, and respect for people.

This book set breaks down Toyota's 13 core pillars and shows how they work together to eliminate waste, ensure quality, and increase productivity. You'll discover: The historical roots of TPS-from Sakichi Toyoda's self-stopping loom to Taiichi Ohno's system-wide innovations after WWII How Kiichiro Toyoda developed the Just-in-Time concept to eliminate overproduction How Toyota built a system of continuous improvement (kaizen) using the PDCA scientific method Why jidoka empowers machines and people to prevent defects in real-time How TPS principles apply not just in Japan-but across global industries This box set includes Books 7 through 17 in the TPS Series-perfect for professionals who want to accelerate learning and drive lean transformation in their own organizations.

If you're serious about understanding the thinking behind Toyota's success and want a practical, in-depth, and historical overview, this set will guide you through the full system step by step.

This book set breaks down Toyota's 13 core pillars and shows how they work together to eliminate waste, ensure quality, and increase productivity. You'll discover: The historical roots of TPS-from Sakichi Toyoda's self-stopping loom to Taiichi Ohno's system-wide innovations after WWII How Kiichiro Toyoda developed the Just-in-Time concept to eliminate overproduction How Toyota built a system of continuous improvement (kaizen) using the PDCA scientific method Why jidoka empowers machines and people to prevent defects in real-time How TPS principles apply not just in Japan-but across global industries This box set includes Books 7 through 17 in the TPS Series-perfect for professionals who want to accelerate learning and drive lean transformation in their own organizations.

If you're serious about understanding the thinking behind Toyota's success and want a practical, in-depth, and historical overview, this set will guide you through the full system step by step.